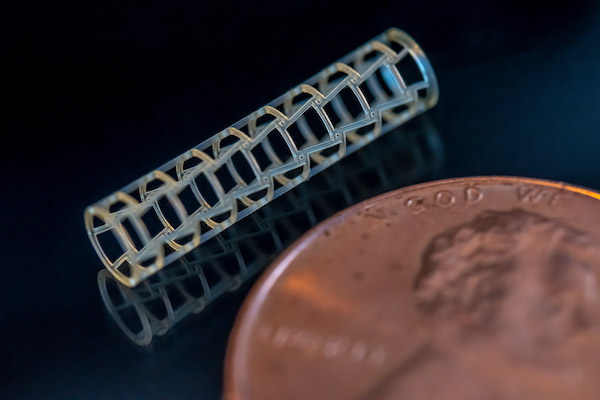

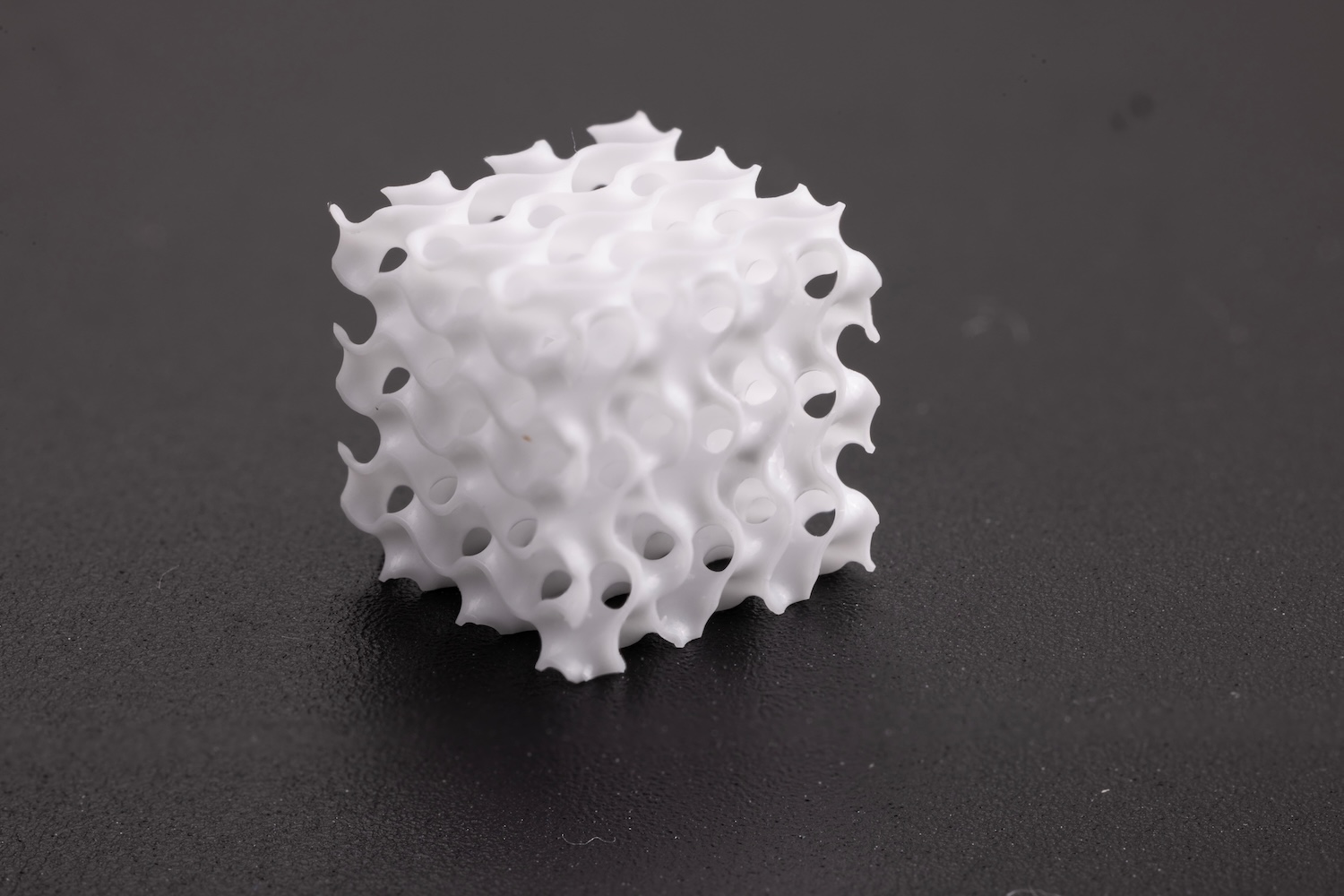

Medical Devices

3D printing has already revolutionized how the medical community treats patients, but this is only the beginning. From stents to prosthetics to surgical planning, 3D printing can be used to print prototypes that optimize patient care. Enter the addition of biocompatible materials, the possibilities are endless. With the ability to achieve 2µm resolution, the microArch series of 3D printers are the perfect tool to print single-use medical components for medical 3D printing applications.

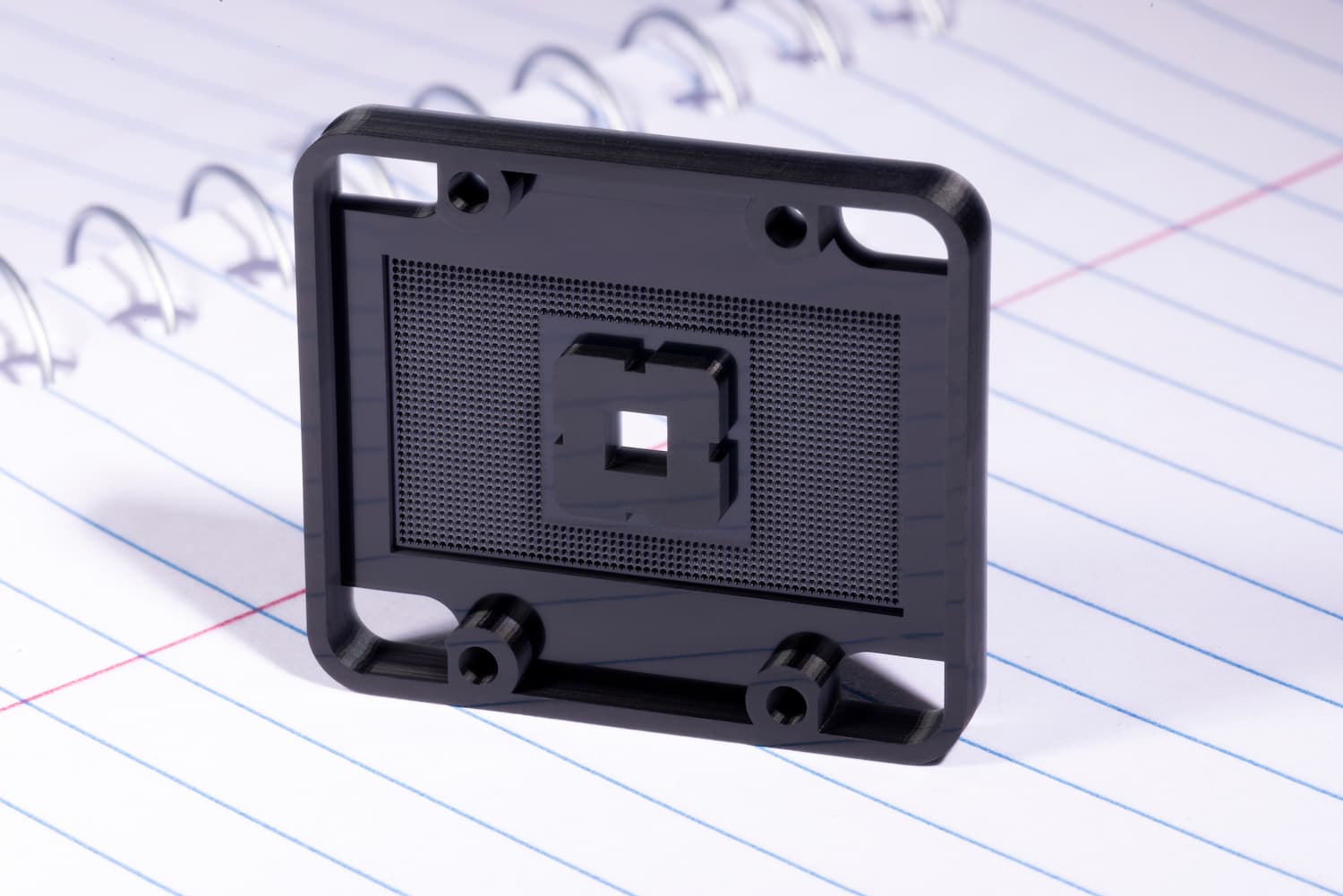

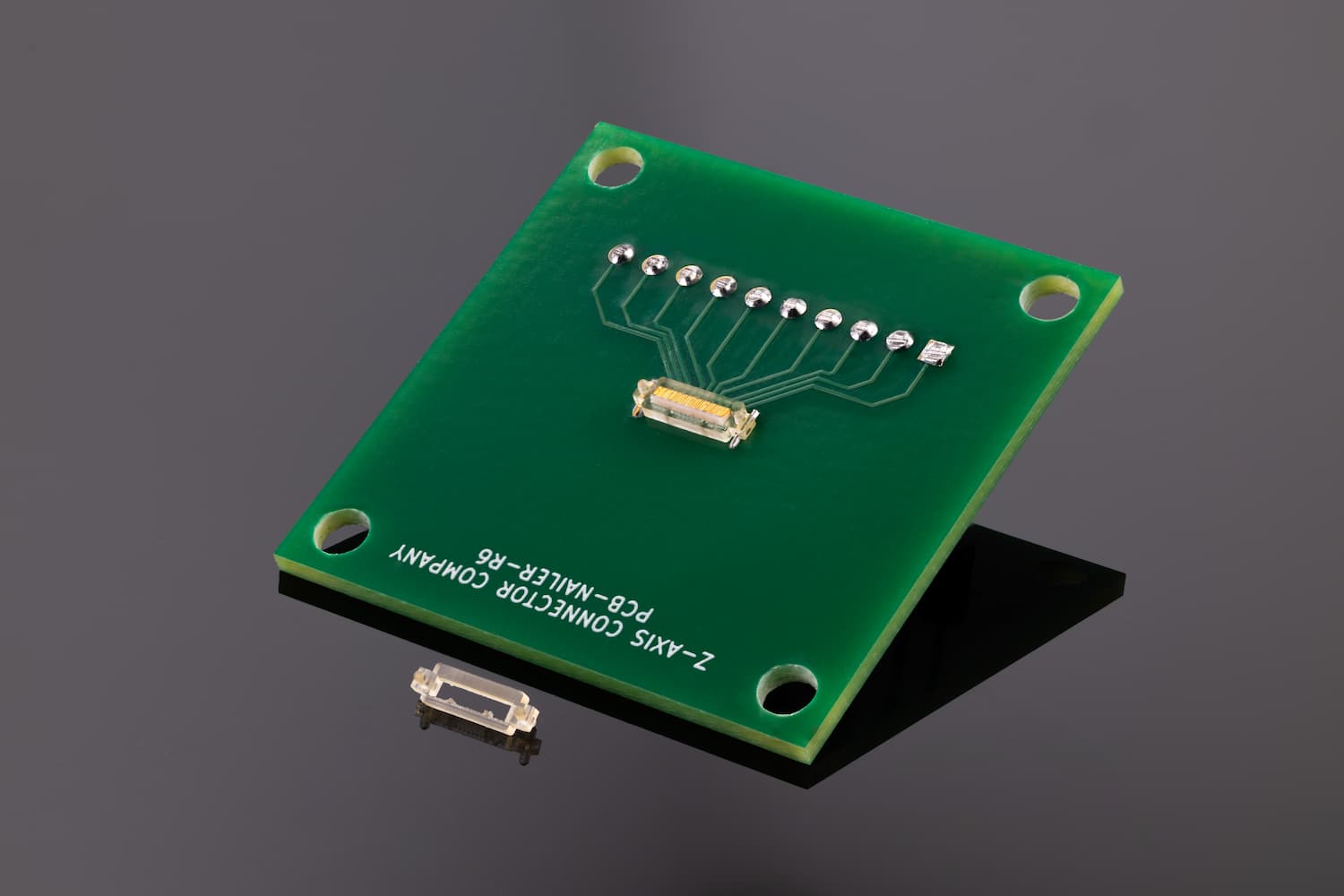

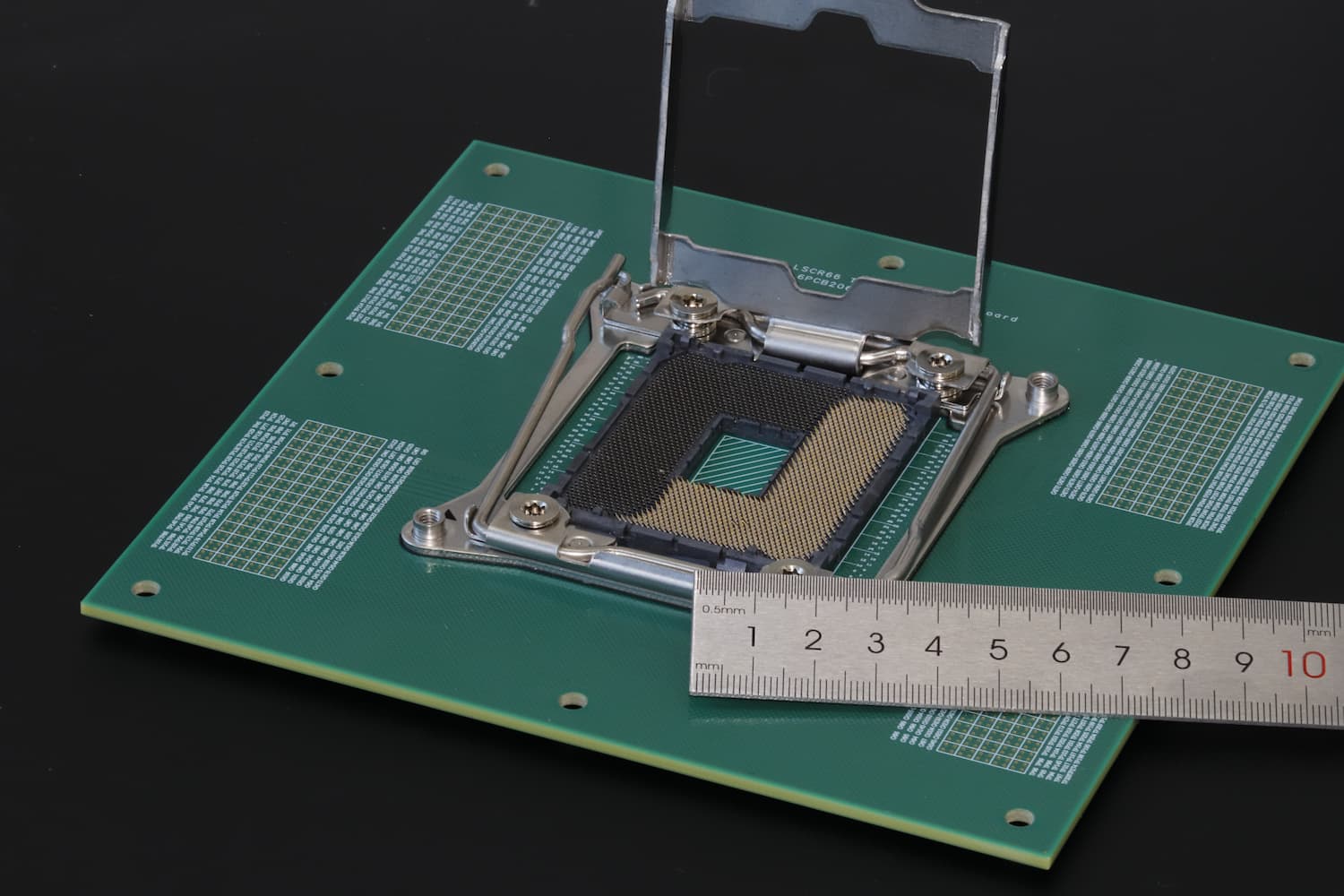

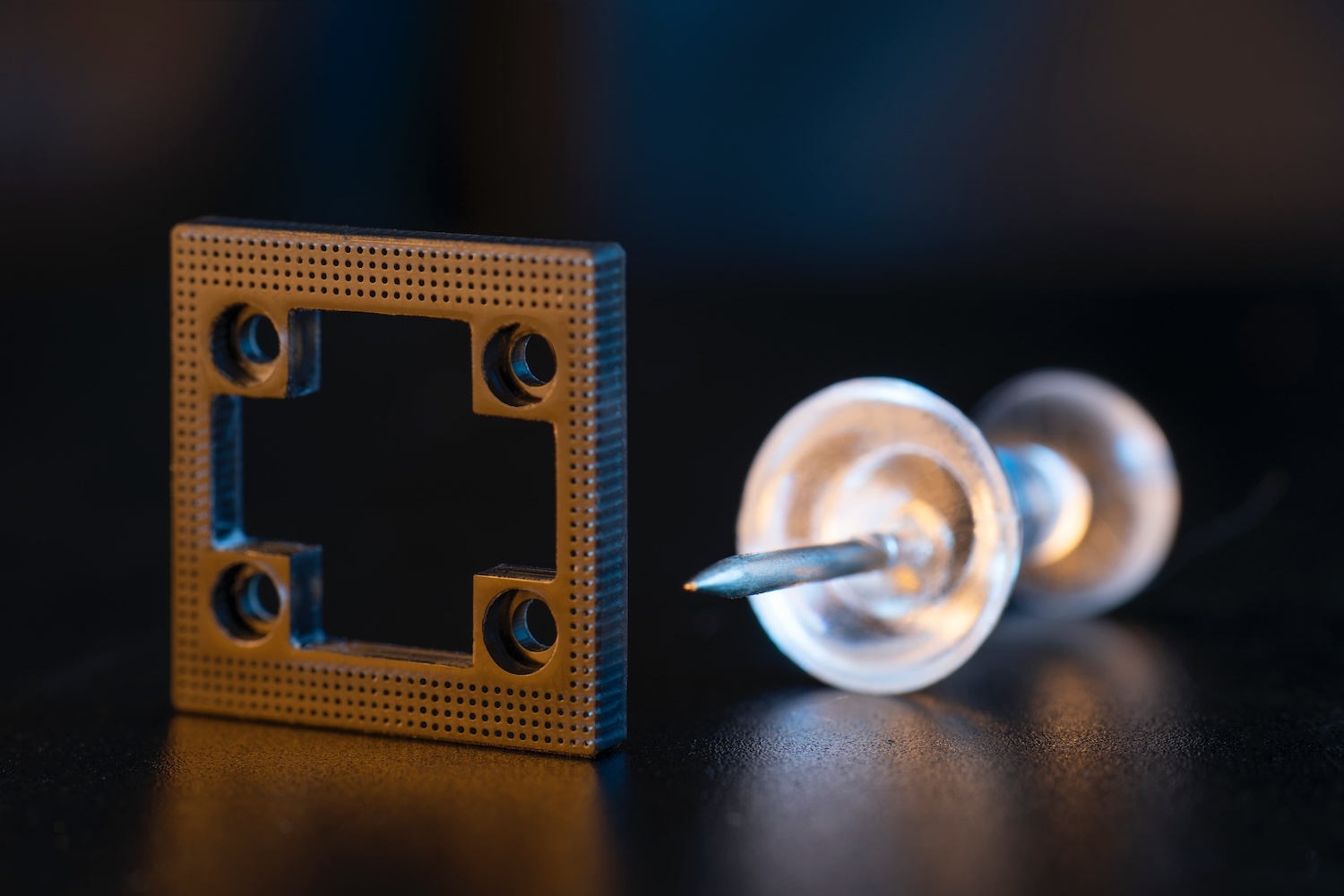

Electronics

Electronics is an industry that has benefited from a large number of new 3D printing applications. Innovation in electrical components and connectors continues to evolve as consumers and businesses look to expand performance while making devices that are smaller and smaller. This has challenged the connector industry, as traditional manufacturing techniques start to become less viable for production. Micro 3D printing offers new ways to produce these complex—and small—designs.

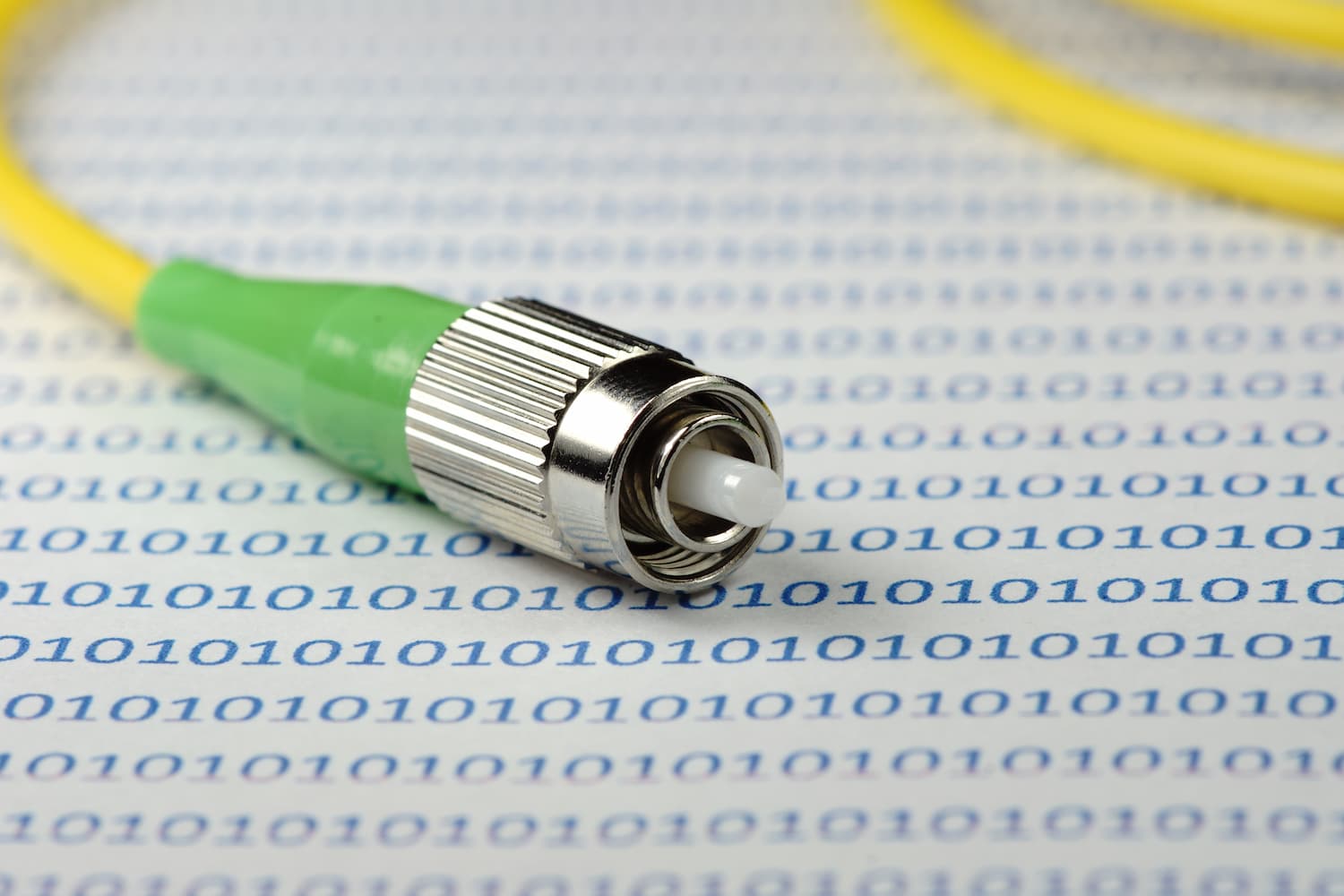

Fiber Optics

In fiber optic systems, precision isn’t optional — it’s essential. Even the smallest misalignment can cause signal loss, reflection, or failure. As devices become smaller and data demands grow, traditional manufacturing methods are hitting their limits.

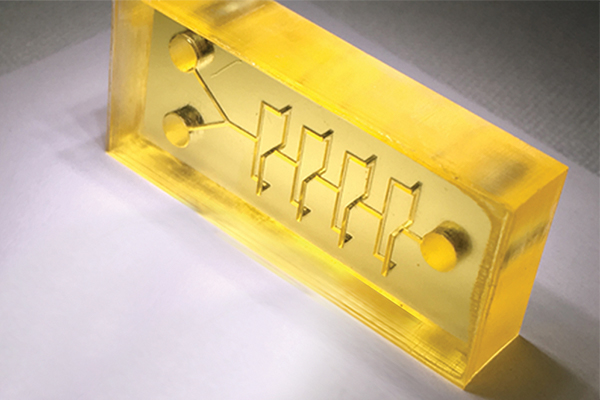

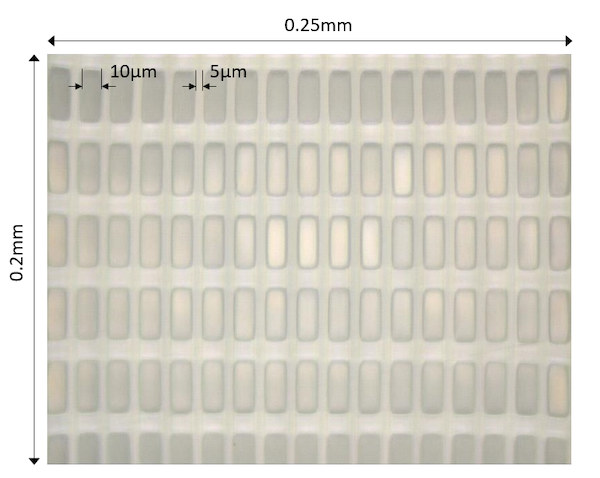

Microfluidics

Various industries have begun to implement microfluidic technologies for both production and development applications. The world of medical and drug research continues to find ways to mimic the human body through tools like Lab-on-Chip and other devices. The micro 3D printing of these products opens up new capability to not only create more accurate and complex systems, but to do so at a cost and speed that is currently not attainable.

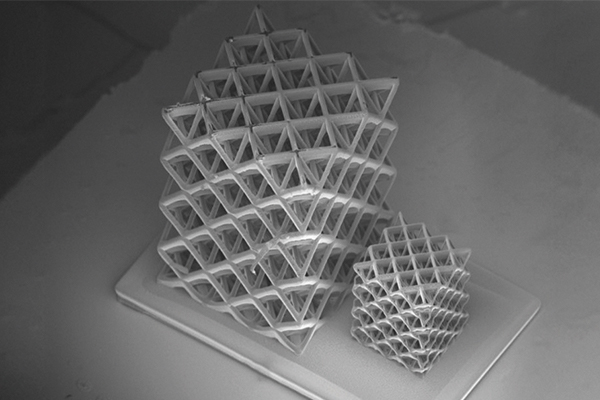

Education / Research

The world of innovation is continually getting bigger, but parts are getting smaller and smaller. The innovators of tomorrow are the students of today. By using micro-scale AM platforms, academia is offered the tools to push the boundaries of product design, drug discovery, microfiltration, and MEMS research, widening the breadth and discovering a wide range of new 3D printing applications.

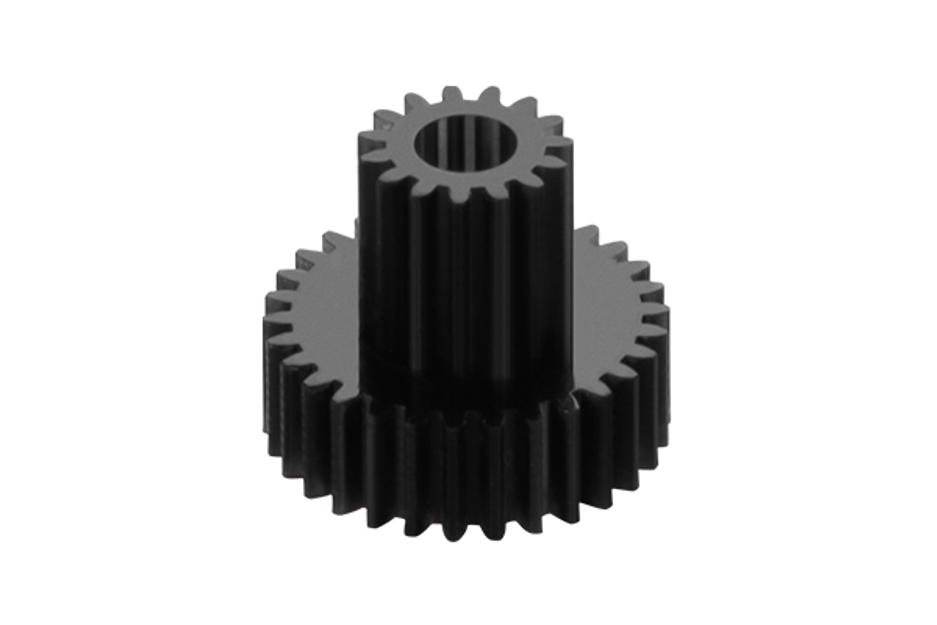

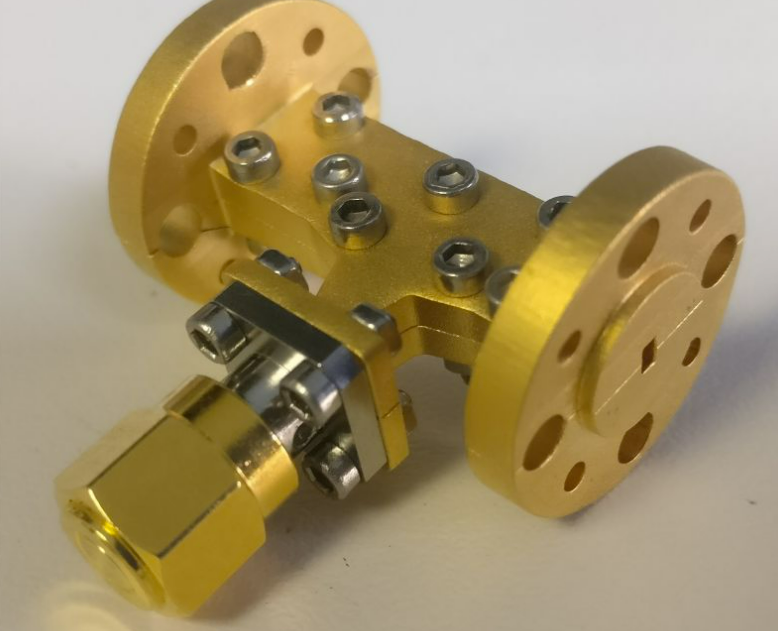

Micro Mechanical Devices

Valves, pumps, sensors, speakers, microphones—any application where capability and performance is expanded through the use of small, high-precision components. These components are difficult and expensive to mold or machine today. The microArch series opens up a new range of capability and geometric freedom that has been historically out of reach for current additive manufacturing platforms.

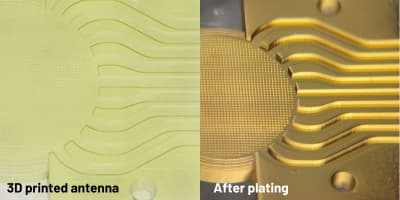

RF & Microwave

In the realm of RF & Microwave engineering, precision and innovation are paramount. Enter the world of Micro 3D Printing—an evolutionary leap in manufacturing technology revolutionizing the way we approach RF & Microwave applications.

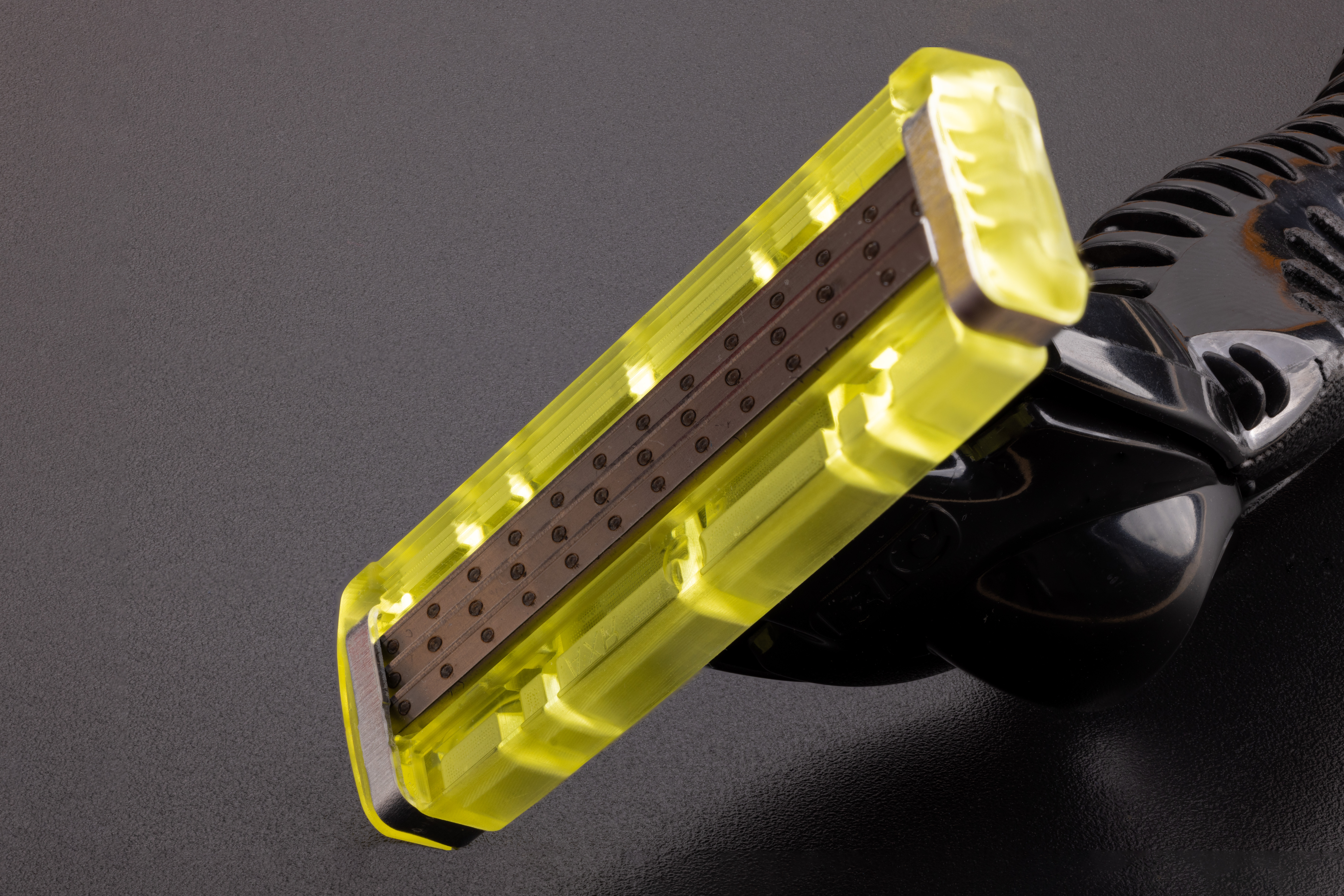

Personal Care & Consumer Products

High-precision 3D printing is revolutionizing the world of personal care and consumer products, offering unparalleled benefits for product designers and manufacturers who require high-precision and tight tolerances for products such as razors, hearing aids, and personal electronics.