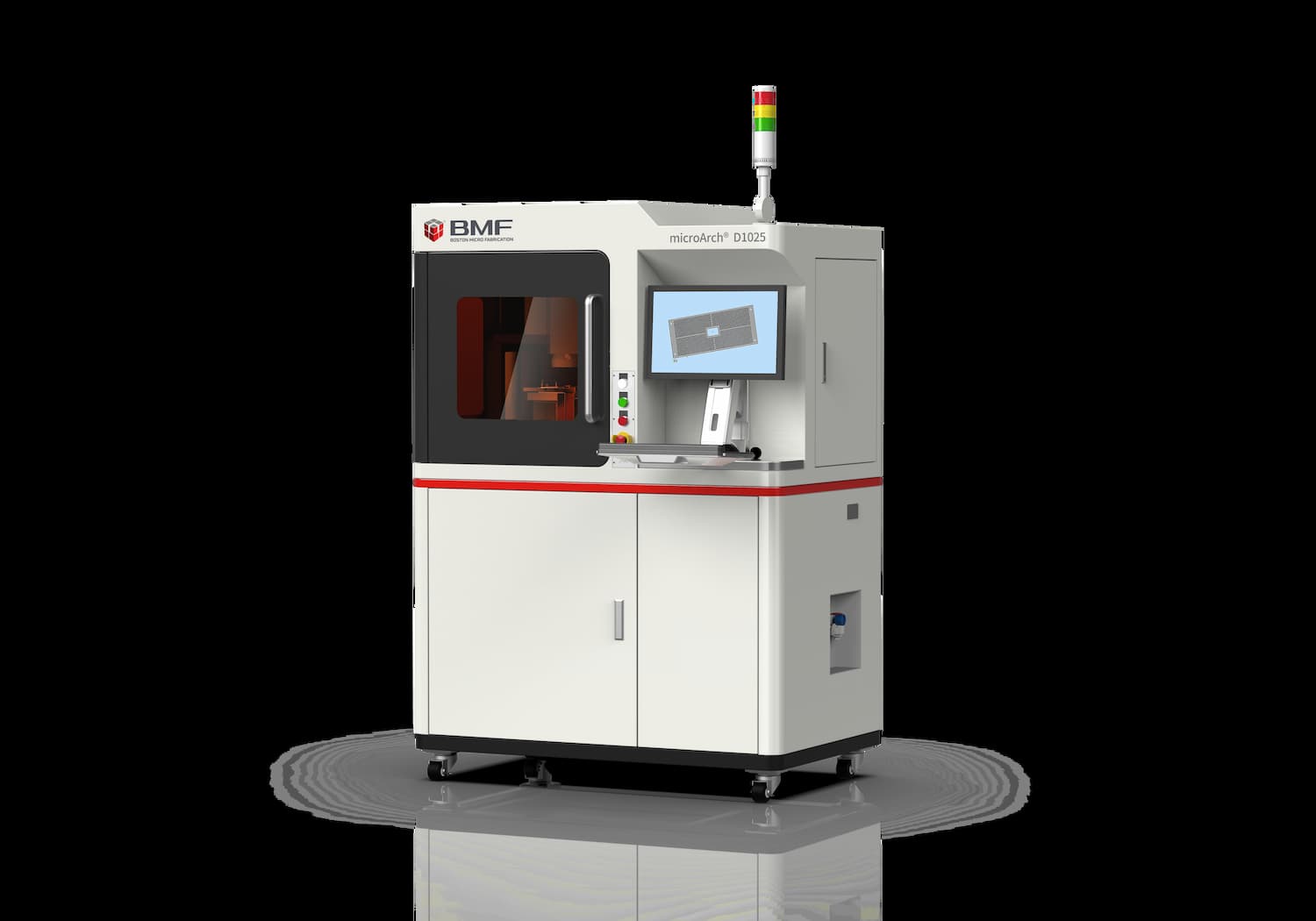

Dual Resolution 3D Printer

Powered by PµSL, the dual resolution microArch D1025 prints in either 10µm or 25µm resolution, or in hybrid mode with both resolutions in different layers. With improved built-in automation, this capability enables greater efficiency – saving time, resources and cost. Delivering the same ultra-high resolution, accuracy and precision BMF is known for, the new D1025 will revolutionize the prototyping and production of parts requiring micron-level precision and repeatability.

[Efficiency + Versatility]²: Meet the microArch D1025

The microArch D1025 is an ideal choice for researchers and manufacturers seeking versatility with the ability to print at two different resolutions. This flexibility enhances efficiency and is complemented by advanced built-in automation features.

Features

- 10µm and 25µm switching: Print with higher resolution when tighter tolerances are needed, or switch to lower resolution for faster printing

- Improved DLP projection: Larger projection zones resulting in faster print times while still producing high-precision parts

- Automatic calibration system: Quickly and automatically calibrate the level of the platform, membrane, and roller, decreasing printer turnover time

- Automatic printing parameters: Print settings for roller frequency and resin leveling delay times are automatically set according to the printing area and material viscosity when using automatic mode. Users still have full manual control if desired

- Automatic resin adjustment: Automatically and accurately adjust resin (viscosity<5DOcPs) amount in vat to achieve a suitable resin level height

- Magnetic platform: Easy to install and remove printing platform for quicker production turnaround time

- Side-shifting membrane: No need to remove or reinstall the membrane in between builds, which increases uptime

- Scraper and roller: Eliminate air bubbles and reduce leveling time

- Resin VAT heating system: Suitable for more complex environments and diverse materials

PµSL Technology

The microArch D1025 is based on BMF’s innovative projection micro stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.