INTRODUCING OUR NEWEST SOLUTION

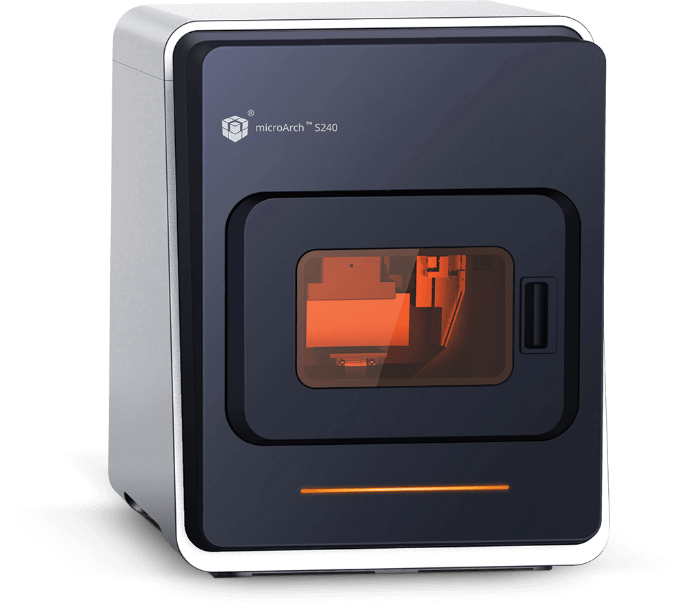

microArch S240

Micro-Precision 3D Printer

Micro-Precision 3D Printer

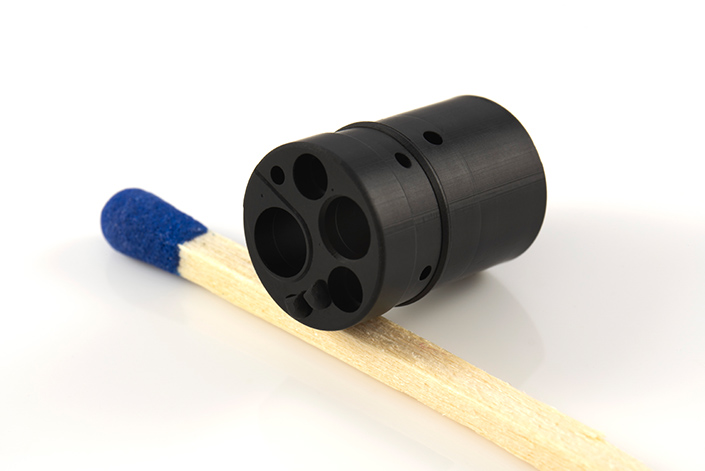

The microArch® S240 is the perfect choice for micro 3D printing with faster printing speeds, a larger build volume and the ability to print with engineering-grade materials – specifically designed to meet the needs of industrial production.

Less time

Less Money

More Success

Faster Printing + Engineering-Grade Materials

Fastest Print Speeds

Up to 10x Faster

Larger Build Volume

100 × 100 × 75MM / 750 cm3

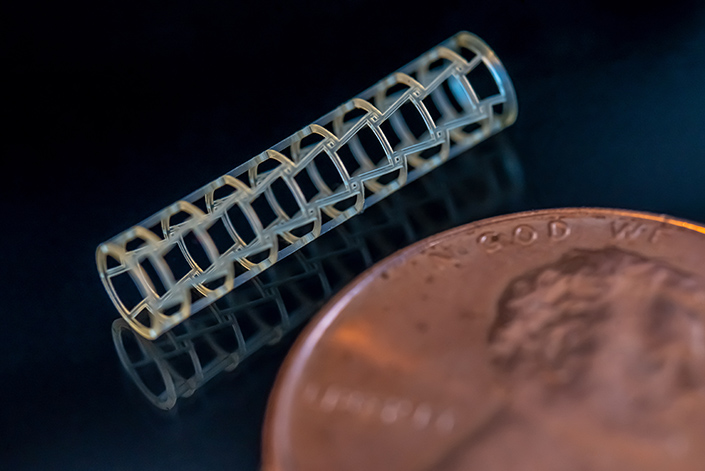

Industrial-Grade Composites and Ceramics

Ideal for Production

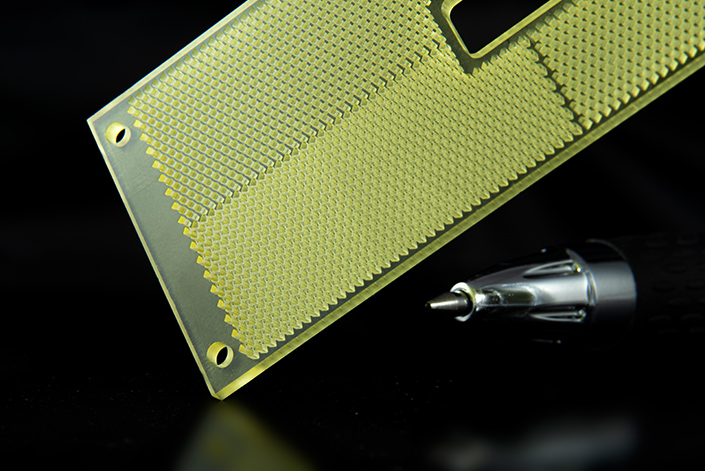

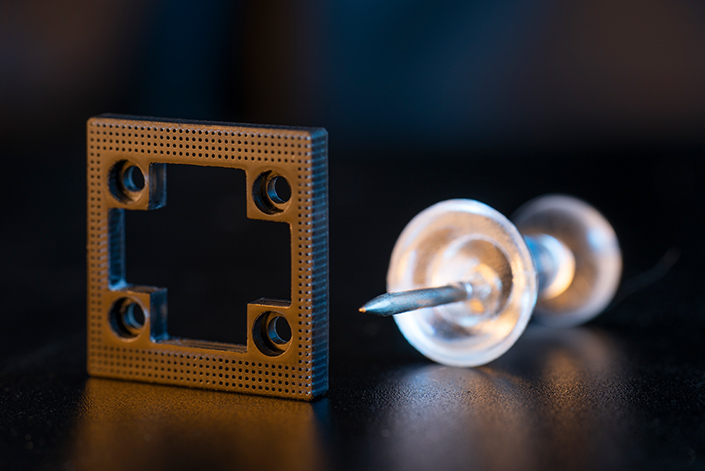

Resolution × Accuracy × Precision

The microArch S240 offers the same unparalleled quality that BMF is known for, but with additional first-class attributes so you can achieve the most exact finished part possible [True to CAD].

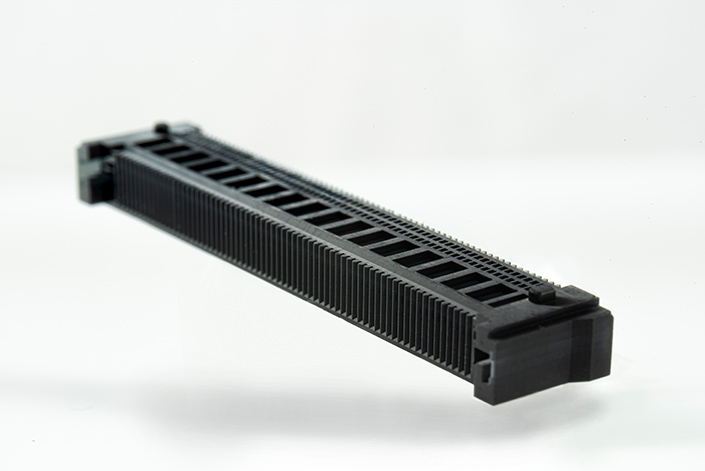

- Larger build volume allows for production of much bigger parts and much higher throughput.

- Advanced roller system spreads layers in seconds, resulting in a build speed of up to 10× faster.

- Ability to handle higher viscosity materials (up to 20,000Cp), resulting in the production of stronger, functional parts.

- Ability to print industrial-grade composite polymers and ceramics.

- Advanced end-part features, including mirror finish, sharp edges, and smooth channels.

PµSL Technology

The microArch S240 is based on BMF’s innovative projection micro stereolithography (PµSL) technology, a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.

PRINTING TECHNOLOGY

PμSL

LIGHT SOURCE

UV-LED

LIGHT WAVELENGTH

405nm

PRINTING MATERIAL

Photosensensitive resins, ceramic

INPUT DATA FILE FORMAT

STL

OPTICAL RESOLUTION

10µm

PRINT SIZE

mode 1: 19.2 × 10.8 × 75mm

mode 2: 100 × 100 × 75mm

mode 3: 100 × 100 × 75mm

mode 2: 100 × 100 × 75mm

mode 3: 100 × 100 × 75mm

LAYER THICKNESS

10-40μm

TOLERANCE

+/- 25μm

POWER SUPPLY

2kW

PRINTER DIMENSIONS

650(L) × 700(W) × 790mm(H)

PRINTER WEIGHT

350kg

VOLTAGE

110-220V

CERTIFICATIONS

CE