BMF and 4D Biomaterials Partner to Bring Bioresorbable Materials to Micro 3D Printing

Partnership Enables Uncharted Micro 3D Printing Applications for BMF’s Medical Device Manufacturing Customers

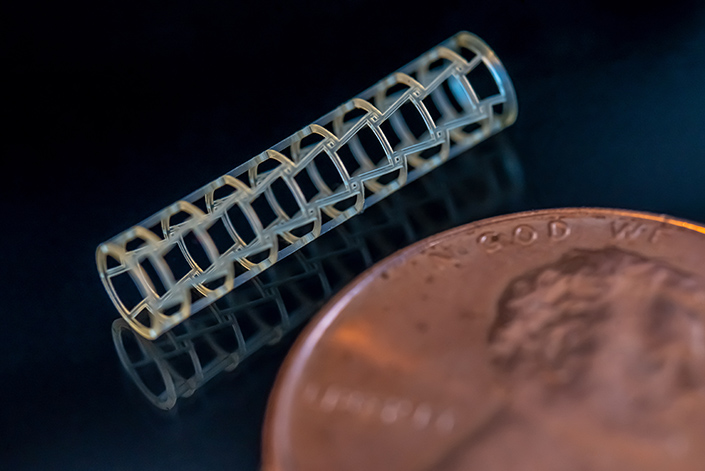

Boston, MA and Nottingham, UK – December 7, 2021 – Boston Micro Fabrication (BMF), the pioneer in microscale 3D printing systems and UK-based 3D printing materials company, 4D Biomaterials today announce the capability to print micro-scale geometries using 4Degra® bioresorbable materials. This achievement marks the first time a bioresorbable material has been printed using micro 3D printing and will revolutionize the way implantable medical devices are manufactured in the future.

Aimed at creating biocompatible and bioresorbable micro-scale medical devices, the joint innovation has a variety of applications and opportunities for medical device manufacturers and innovators, ranging from micro-scale rigid orthopaedic devices and fixations through to micro-scale soft tissue applications.

The partnership combines BMF’s innovative projection micro stereolithography (PµSL) approach with 4D Biomaterials’ 4Degra resin inks which together will help to solve design and biocompatibility issues for medical device manufacturers, opening up new opportunities for implantable devices and improving patient care.

BMF has a growing group of customers working to develop new micro-scale medical devices. Its approach is gaining favor within multiple markets as companies look to solve design problems by making components and parts smaller and smaller. “Our customers continue to seek out solutions to miniaturize and now with bioresorbable material options, a whole new range of devices are possible,” said BMF CEO John Kawola. “Miniaturization in medical device development has been held back by the limitations of traditional manufacturing methods and the materials available. The BMF and 4D Biomaterials partnership is working toward eliminating those barriers.”

“This partnership with BMF represents a huge opportunity when it comes to printing micro-structures. We are enabling medical device companies to think about 3D printing micro-resorbable implants for the first time,” said Philip Smith, CEO of 4D Biomaterials. “The bioresorbable polymers market is estimated to be USD 1.0 billion in 2021 and is projected to reach USD 1.6 billion by 2026 We are already seeing the demand from this market growth as the range of applications continues to widen with the advancements in hardware, software and materials technology.”

For more information about how materials like 4Degra can be used for micro 3D printing applications in the medical device industry, please visit www.bmf3d.com.

About BMF – Boston Micro Fabrication

Boston Micro Fabrication (BMF) specializes in micro precision 3D printing. The company’s microArch system uses a 3D printing approach called PμSL (Projection Micro Stereolithography) that leverages light, customizable optics, a high-quality movement platform and controlled processing technology to produce the industry’s most accurate and precise high-resolution 3D prints for product development, research and industrial short run production. The technology represents a true industry breakthrough by empowering product manufacturers to capitalize on the benefits of 3D printing without sacrificing quality or scale.

Founded in 2016, BMF has offices in Singapore, Boston, Shenzhen and Tokyo. For more information on BMF please visit www.bmf3d.com or follow the company on LinkedIn.

About 4D Biomaterials

A spin-out from the Universities of Birmingham and Warwick, based on 15 years of academic research, 4D Biomaterials has developed 4Degra® – a new class of bioresorbable 3D-printing resin inks for implantable medical device applications. The biocompatible shape memory photopolymers can be 3D-printed into flexible or rigid devices that promote tissue repair, then controllably degrade into benign, resorbable by-products.

4Degra resin inks are based on revolutionary polycarbonate urethane chemistry and can be printed using PμSL and digital light processing (DLP) to create finely detailed implantable medical devices that support the body‘s natural healing processes before degrading into harmless by-products that are absorbed and removed through normal metabolic processes. The chemistry can also be tuned so that the 3D-printed product exhibits a wide range of mechanical properties: from soft, pliable, adipose tissue-like behaviour to firm and rigid bone-like properties. For more information, please visit www.4dbiomaterials.co.uk or watch the technology explainer video here: https://vimeo.com/553243984