Press Release •

October 16, 2024

Boston Micro Fabrication Expands Material Compatibility for microArch 3D Printers with Industry-Leading High-Performance Resins

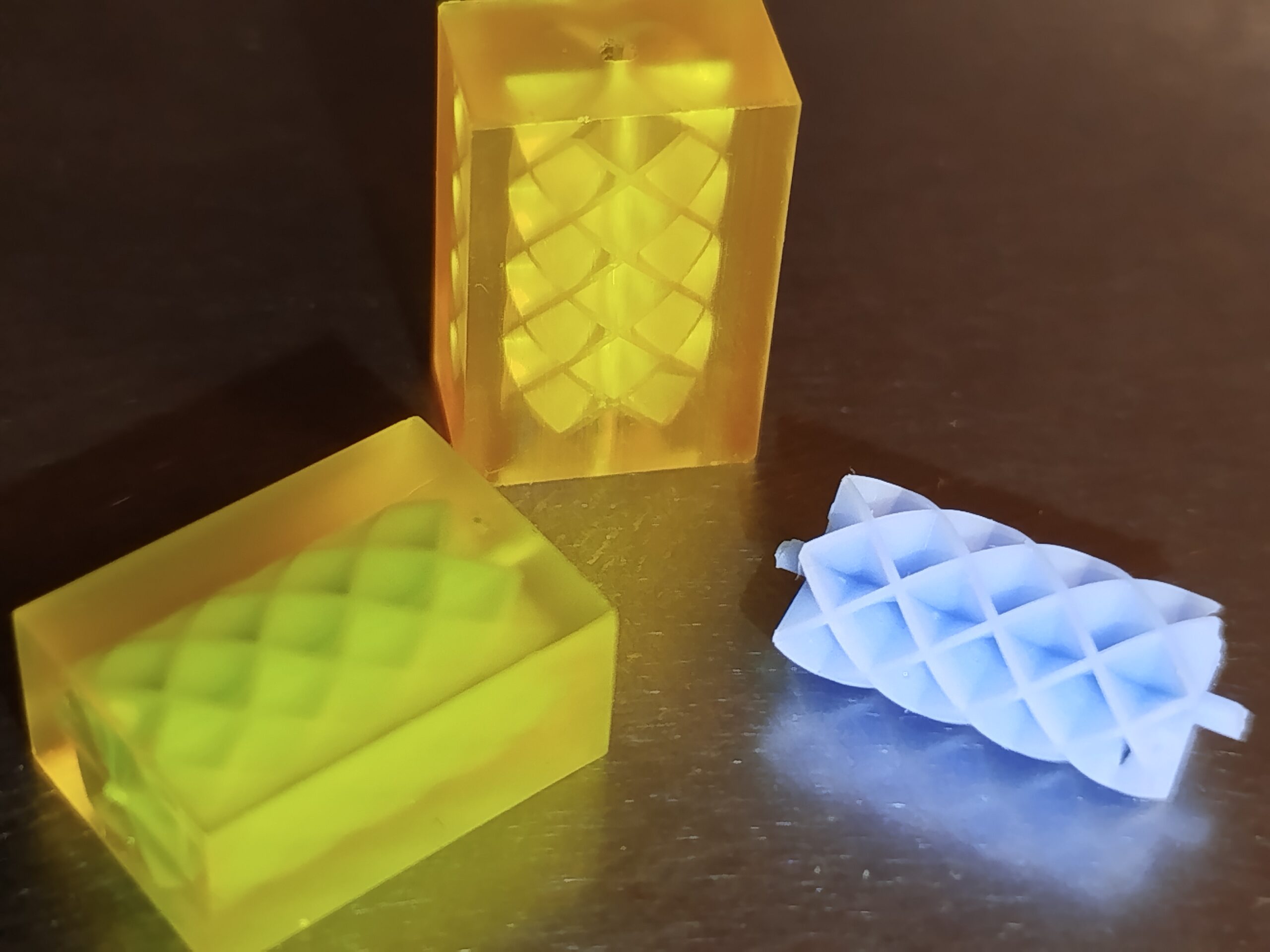

Boston Micro Fabrication (BMF), a leader in ultra-high precision 3D printing solutions, is introducing four new materials for its microArch series 3D printers. These advanced materials, including 3D Systems’ Figure 4® HI TEMP 300-AMB, BASF Ultracur3D 3280 and BMF resins HTF and SR, further enhance BMF's ability to meet the diverse and demanding needs of industries like aerospace, medical devices, electronics, and biotechnology.