3Dprint.com •

January 9, 2025

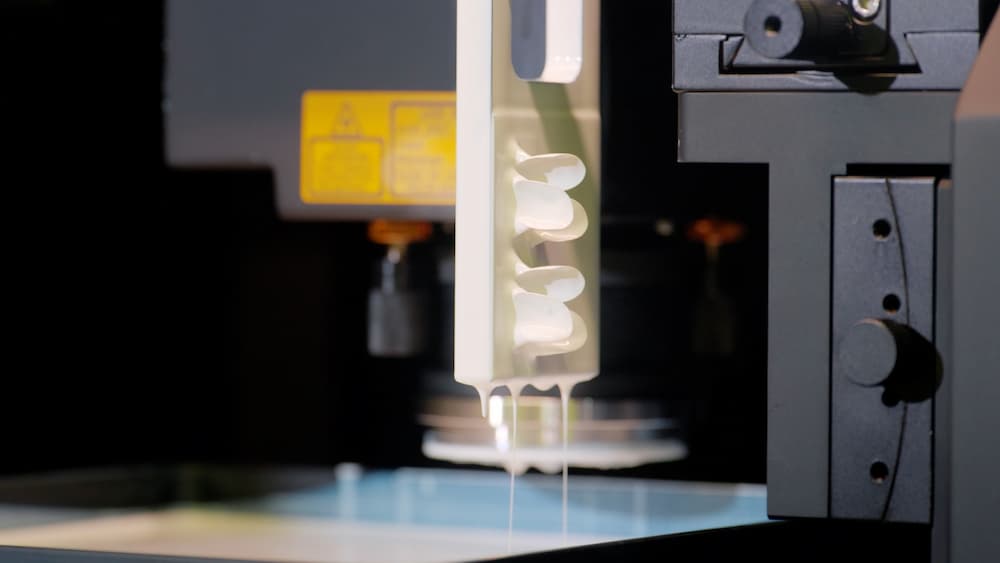

3D Printing and Dentistry: 2024’s Progress, 2025’s Promise

Boston Micro Fabrication’s CEO John Kawola explains: “There are new advances in resins and materials approved for dentistry, making additive manufacturing a more attractive, versatile, and realistic option. We’ve also seen 3D printing push new bounds in applications where there’s a need for higher precision and thinner materials, such as veneers.