UltraThineer Press •

November 19, 2024

Boston Micro Fabrication Opens Lab to Support Testing, Manufacturing and Sales of Zirconia UltraThineer Veneers

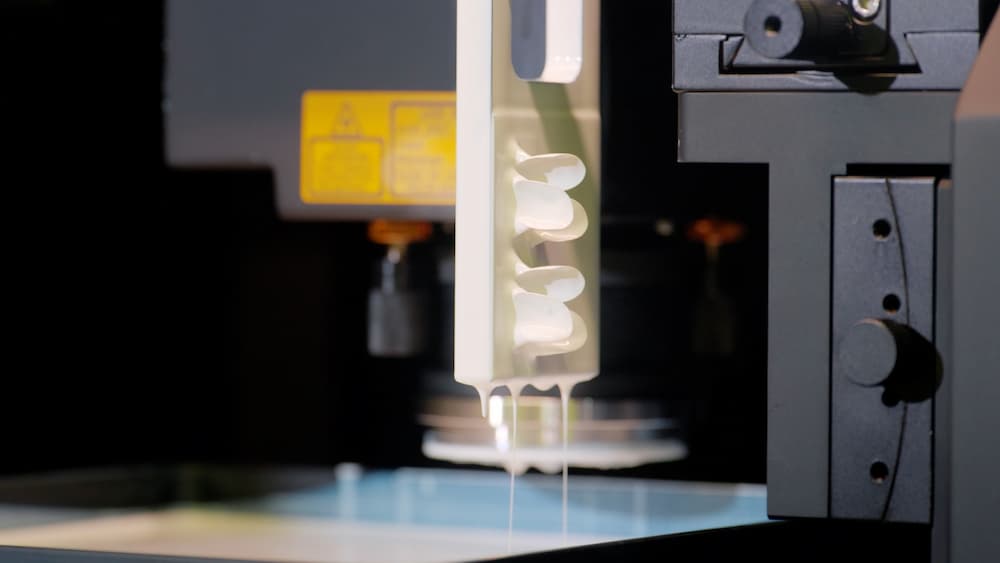

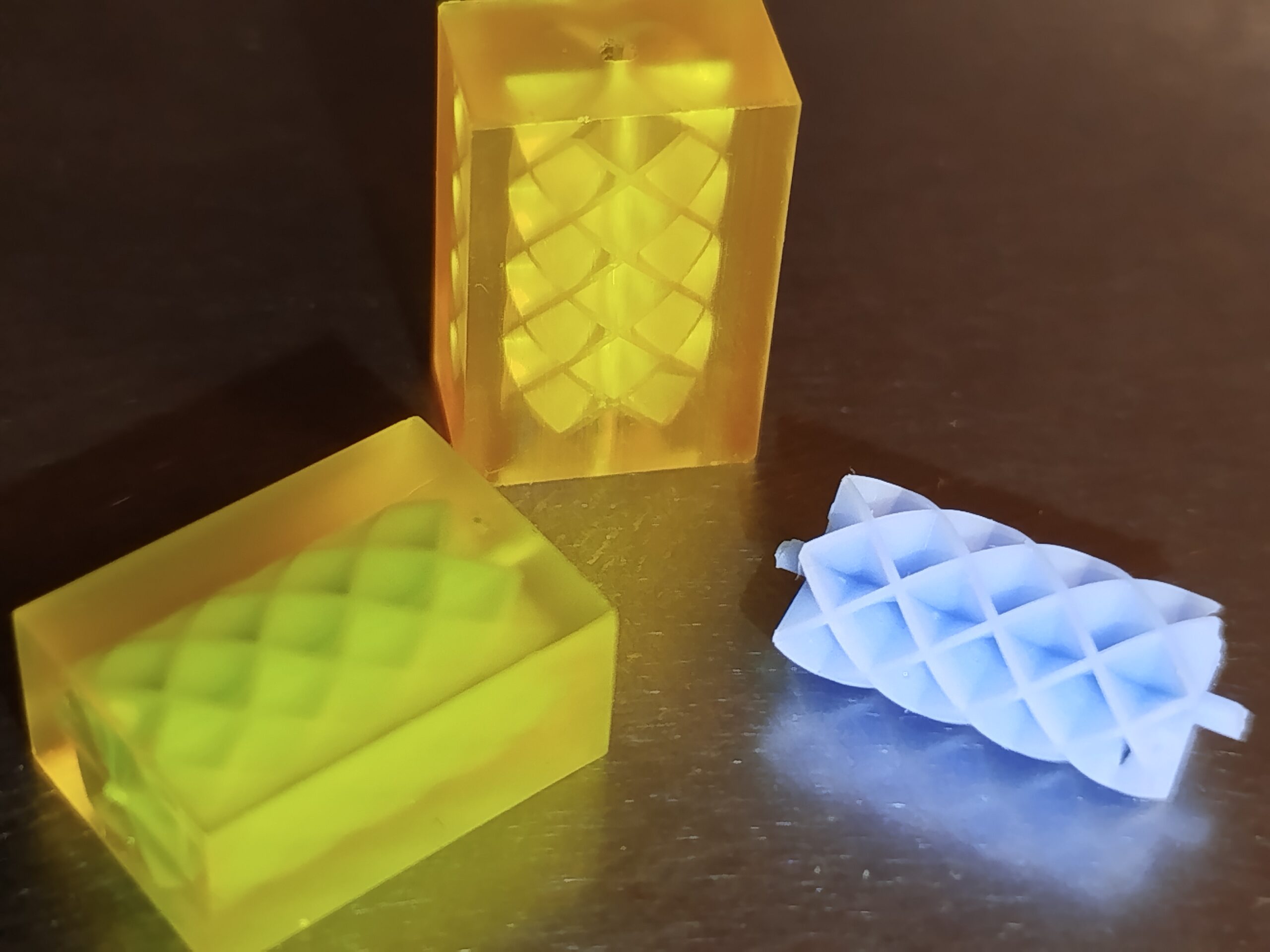

Boston Micro Fabrication (BMF), a leader in advanced manufacturing solutions for ultra-high precision applications, today opened the UltraThineer™ Lab at its U.S. headquarters in Maynard, Mass. to advance the production of UltraThineer veneers. The UltraThineer Lab will house BMF’s proprietary technology, projection micro stereolithography (PµSL), to custom manufacture cosmetic veneers that are three-times thinner than traditional veneers, enabling dentists to offer the world’s thinnest custom veneers to their patients in the U.S.