Fabbaloo •

September 14, 2021

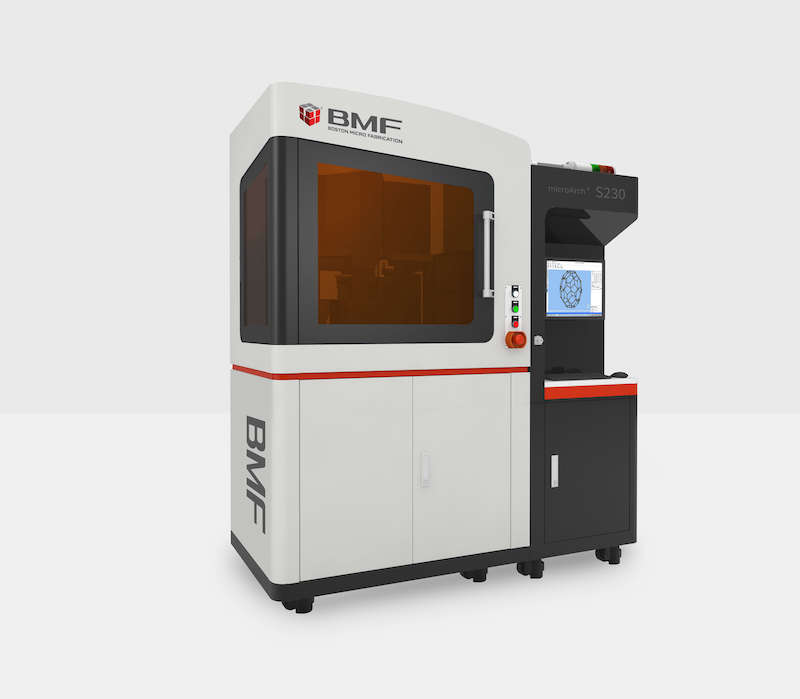

BMF’s microArch S230 3D Printer

BMF announced a new microArch 3D printer, the S230. The Boston-based company develops 3D printers with extreme resolution. Their current line of equipment, for example, offers a resolution of up to an incredibly tiny 2μm (that’s 0.002mm).