3Dprint.com •

December 9, 2021

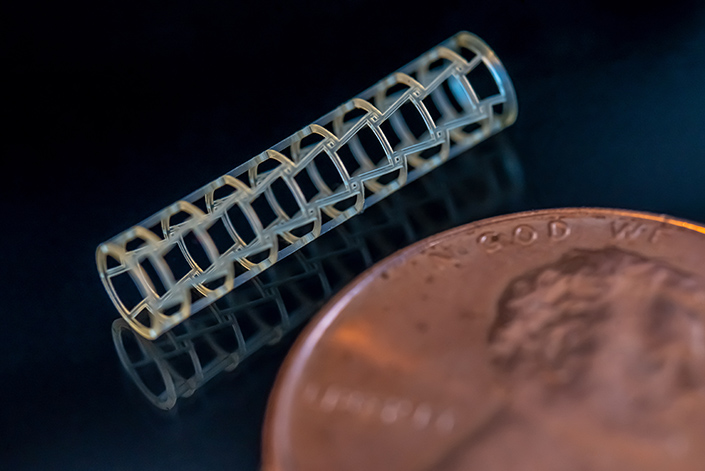

Micro Medical Devices to Be Developed by BMF and 4D Biomaterials

We’re still awaiting the nanobot medical revolution that was promised by science fiction decades ago and, at this point, we’re probably less and less sure that we’d want such a thing to begin with. Nevertheless, progress is being made in the world of tiny medicine. Boston Micro Fabrication (BMF) has teamed with British materials firm 4D Biomaterials to enable the 3D printing of microscale, bioresorbable, microscale medical devices.